Performance features

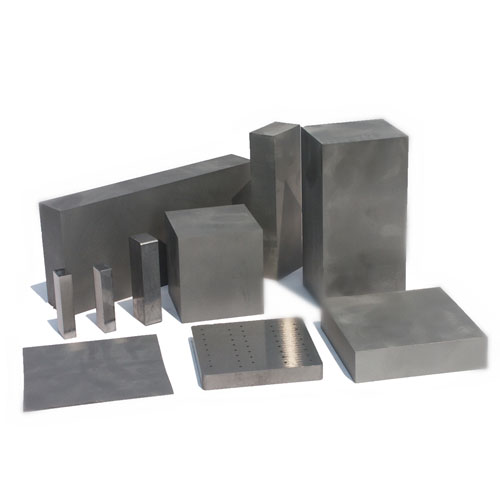

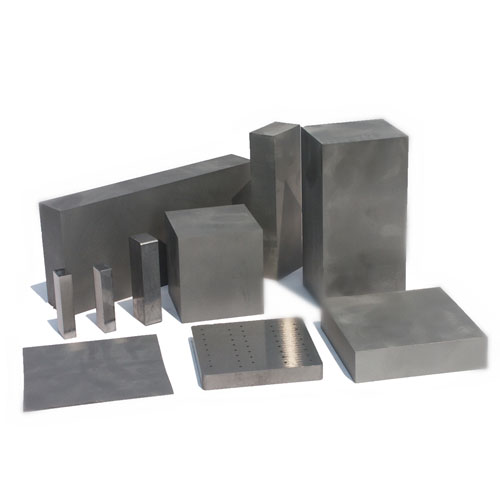

Tungsten carbide sheet for IC mould

| Grade | Co | Density g/cm3 | Hardness HRA | T.R.S N/mm3 | Application |

|---|---|---|---|---|---|

| KD10 | 10 | 14.4 | 91.5 | 4300 | Suitable for stamping of copper and aluminum sheets, the thickness of copper and aluminum less than 0.2mm. |

| KD12 | 12 | 14.3 | 90.5 | 4000 | Suitable for stamping and cutting copper, aluminum and steel sheet. |

| KD20 | 13 | 14.25 | 91 | 4100 | With good applicability,suitable for stamping of copper and aluminum sheets. |

| KD36 | 15 | 14 | 90 | 3900 | suitable for stamping of EI silicon steel sheet, steel plate cold commercial and stainless steel plate. |

| Grade | Co | Density g/cm3 | Hardness HRA | T.R.S N/mm3 | Application |

|---|---|---|---|---|---|

| KD40A | 12 | 14.2 | 89.5 | 3300 | suitable for stamping of upper and lower mould for coll rolled plate. |

| KD45A | 15 | 13.9 | 88 | 3500 | suitable for stamping of upper mould for silicon steel sheet and lower mould for coll rolled plate. |

| KD55 | 20 | 13.5 | 86.4 | 3100 | Suitable for punching of thick plate under large impact load conditions. |

| Grade | Co | Density g/cm3 | Hardness HRA | T.R.S N/mm3 | Application |

|---|---|---|---|---|---|

| YG6A | 6 | 14.95 | 92.5 | 1800 | Fine-grain size, with good wear resistance, used for processing blades, wear resistance parts etc. |

| YG8 | 8 | 14.8 | 89.5 | 2200 | High bending strength, wear resistance lower than YG6A, used for processing blades, wear resistance parts etc. |

| YG15 | 15 | 14 | 87.5 | 2800 | Used for punch dies, stamping dies and wear resistance parts. |

| YG20 | 20 | 13.5 | 85.5 | 3200 | High bending strength, used for punching dies and other stamping dies. |

| YS2T | 15 | 14.45 | 91.5 | 2350 | Fine grain, with high wear resistance and bending strength, suitable for the dressing of cast iron rolls and high nickel-chromium rolls. |

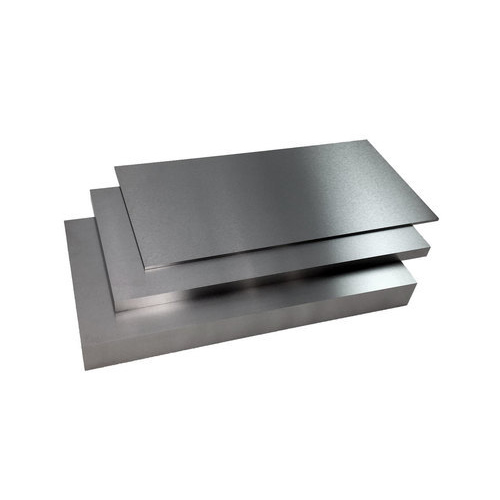

| L(mm) | W(mm) | S(mm) |

|---|---|---|

| 300 | 300 | 20-40 |

| 250 | 250 | 5-50 |

| 200 | 200 | 5-45 |

| 150 | 150 | 5-45 |

| 150 | 130 | 10-45 |

| 150 | 100 | 10-45 |

| 150 | 80 | 10-45 |

| 135 | 135 | 10-70 |

| 125 | 125 | 3-45 |

| 105 | 105 | 2-70 |

| 100 | 100 | 5-70 |

| 100 | 50 | 10-50 |

| 100 | 45 | 10-50 |

| 80 | 55 | 10-50 |

| 80 | 40 | 10-40 |

| 70 | 35 | 5-40 |

| 45 | 25 | 5-20 |

| 35 | 19 | 5-20 |

| 20 | 20 | 5-20 |

| 18 | 13 | 5-20 |

Production technics

Carbide plates are mainly made from wolfram carbide and cobalt powder by powder metallurgy methods. The main production process of sintered tungsten carbide plate is powder milling, ball milling, pressing and sintering. For different uses, the content of WC and Co in tungsten carbide sheet metal is not the same.

Application

Tungsten carbide sheet plate is mainly used to make high-speed die and multi-station progressive die for punching copper, aluminum, stainless steel, cold-rolled sheet, EI sheet, SPCC, silicon steel sheet, hardware, standard parts, upper and lower punches, etc. It is also an excellent material for making high-temperature resistance parts, wear-resistant parts, anti-shielding parts, anti-radiation, and corrosion-resistant parts.

Main Process flow

Powder milling→ formula according to application requirements → wet milling → mixing → crushing → drying → sieving → adding forming agent → redrying → sieving to obtain cemented carbide powder→ granulating → pressing → forming → low-pressure sintering →blanks→Flaw inspection→Packing→Warehousing