hycarbide@gmail.com

Tel:+86-731-22761686

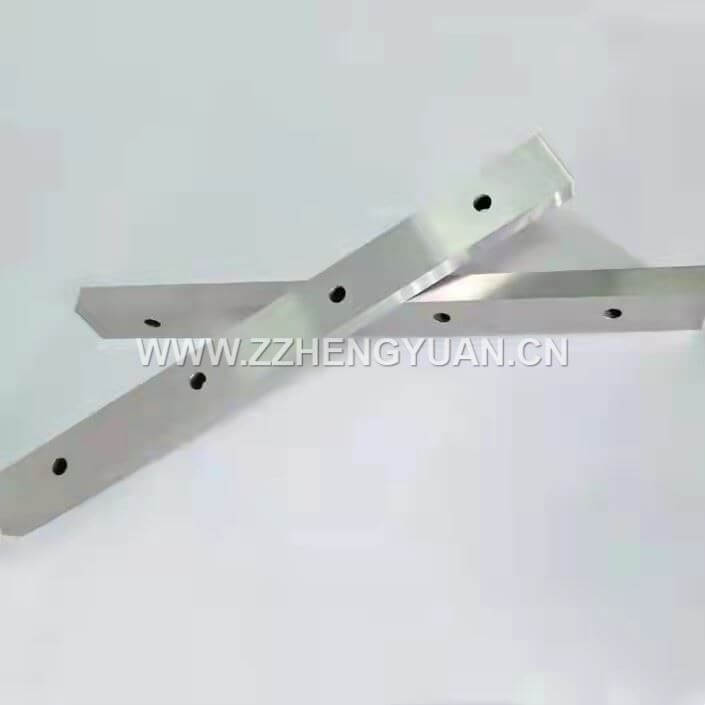

Tungsten carbide strips

Easy to be brazed

excellent wear resistance and toughness

The grade for tungsten carbide strips

| ISO Grade | Grain um | Density g/cm3 | Hardness HRA | T.R.S N/mm3 | Application |

|---|---|---|---|---|---|

| K20 | Medium | 14.6-15.0 | 90-90.5 | 2200-2400 | High hardness,suitable for rough machining of iron,solid wood,dry wood or nonferrous metal,ceramic and other alloys. |

| K30 | Fine | 14.6-15.0 | 90-90.5 | 2600-2800 | Hight toughness, easy to be brazed without heat preservation.Suitable for rosewood, solid wood, pinewood, and other wood with a lot of stammers. |

| K10 | Ultrafine | 14.6-15.0 | 92.5-93 | 1800-2000 | High hardness, suitable for finish machining of iron, nonferrous metal, ceramic and other alloy,semi-finish machining of hardwood, chipboard, MDF and HDF. It's best to use silver soldering. |

| K40 | Coarse | 13.8-14.2 | 87.5-88 | 2800-3000 | High toughness, difficult to break tooth. It's used specially for finger jointing tools. |

| K40 | Medium | 14-14.2 | 85-86 | 1700-1900 | Mainly used for stamping molds and ceramic molds of electronic parts, corrosion-resistant instruments of petroleum machinery, non-magnetic. |

| K10 | Fine | 14.5 | 91 | 3000-3200 | On the basis of ensuring high bending strength, the wear resistance of cemented carbide is enhanced, the cutting edge is dense and sharp, which is conducive to the flatness of processing and has good welding performance. It is used for food packaging, printing, aluminum foil, metalized film, gardens, textile, leather, plastic, rubber and other mechanical blades. |

| YN15 | medium | 13.7-14 | 85-86 | 1700-1900 | Without cobalt, nickel binder, without magnetic, mainly used for stamping moulds and ceramic die of electronic components. |

The size for carbide rectangular strips

| Width (mm) | Length (mm) | Thickness (mm) | Width (mm) | Length (mm) | Thickness (mm) |

|---|---|---|---|---|---|

| 3.5 | 50-320 | 1-3.5 | 19 | 50-320 | 1-19 |

| 4 | 50-320 | 1-4 | 20 | 100-1500 | 1-20 |

| 4.5 | 50-320 | 1-4.5 | 22 | 100-1500 | 1-22 |

| 5 | 50-320 | 1-5 | 23 | 100-1500 | 1-23 |

| 6 | 50-320 | 1-6 | 24 | 100-1500 | 1-24 |

| 7 | 50-320 | 1-7 | 25 | 100-1500 | 1-25 |

| 8 | 50-320 | 1-8 | 26 | 100-1500 | 1-26 |

| 9 | 50-320 | 1-9 | 28 | 100-1500 | 1-28 |

| 10 | 50-320 | 1-10 | 30 | 100-1500 | 1-30 |

| 11 | 50-320 | 1-11 | 32 | 100-1500 | 1-30 |

| 12 | 50-320 | 1-12 | 35 | 100-1500 | 1-30 |

| 13 | 50-320 | 1-13 | 36.6 | 100-1500 | 1-30 |

| 14 | 50-320 | 1-14 | 40.2 | 100-1500 | 1-30 |

| 15 | 50-320 | 1-15 | 45.2 | 100-1500 | 1-30 |

| 16 | 50-320 | 1-16 | 48.8 | 100-1500 | 1-30 |

| 17 | 50-320 | 1-17 | 50.1 | 100-1500 | 1-30 |

| 18 | 50-320 | 1-18 | 60 | 100-1500 | 1-30 |

Production technics

Application

Main Process flow

Powder milling→ formula according to application requirements → wet milling → mixing → crushing → drying → sieving → adding forming agent → redrying → sieving to obtain cemented carbide powder→ granulating → pressing → forming → low-pressure sintering →blanks→Flaw inspection→Packing→Warehousing